I took part in the LEO hack 2025 organised by Magdrive and Imperial College Space Society. During the hackathon the task was to create a prototype of a capture and release mechanism that will enable an active satellite to capture a dead satellite and pull it into a different orbit.

Quote from the brief:

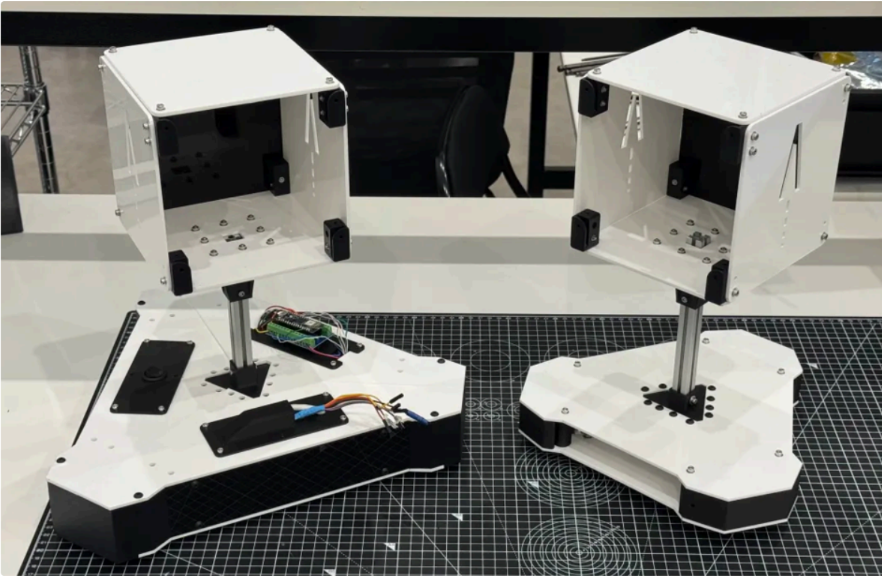

“You need to design a capture and release mechanism for our satellites. This will involve an ‘active sideʼ and a ‘passive sideʼ. You will be able to control the active side and will have power provided to it. Apart from that, you will have driving control over the active satellite. The passive side is located on a ‘passiveʼ robot that emulates a dead satellite. The passive robot sits on ball bearings emulating a ‘2DOF - 0gʼ environment so be careful how much force you exert on it or it will fly away”

Our process:

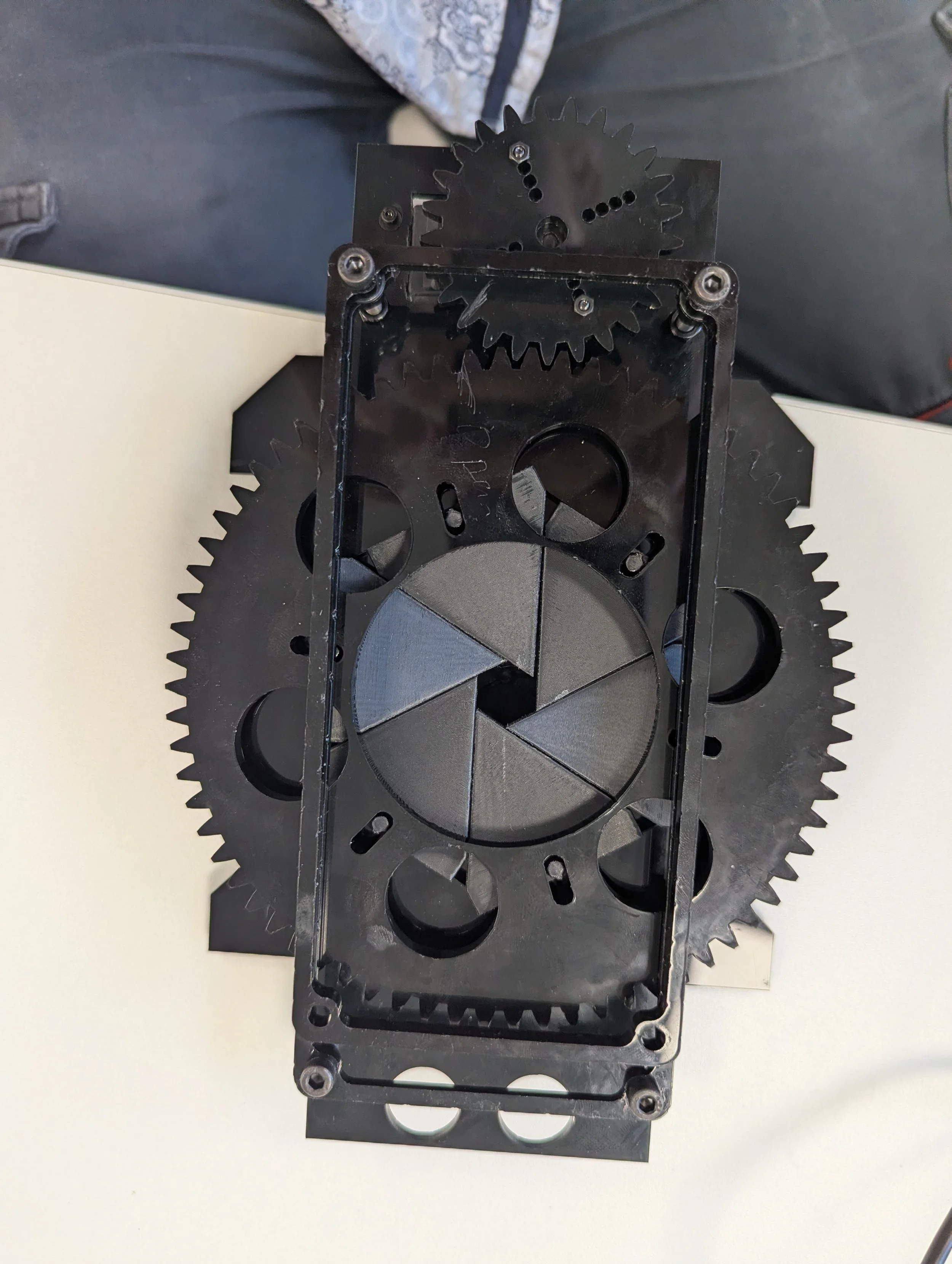

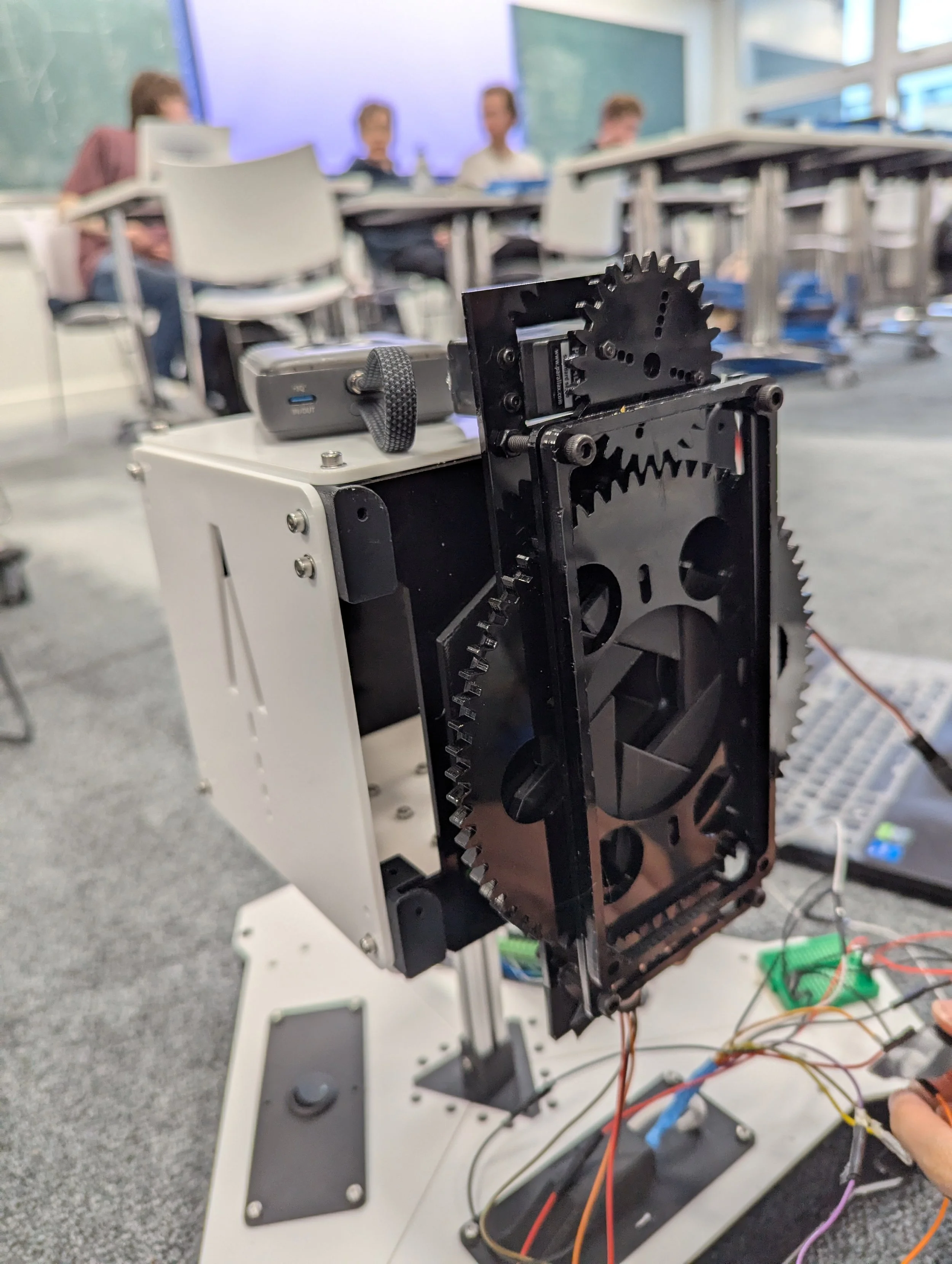

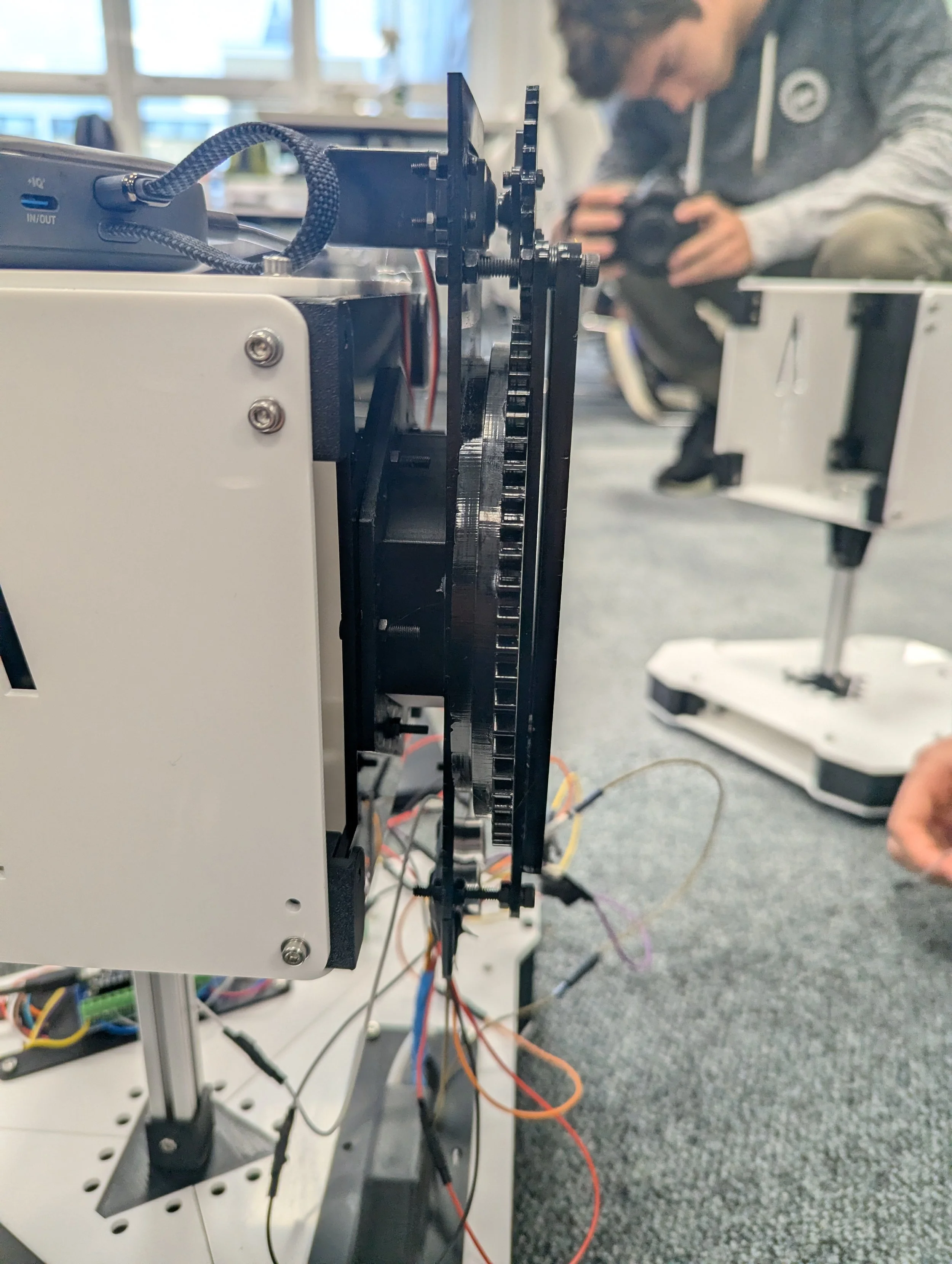

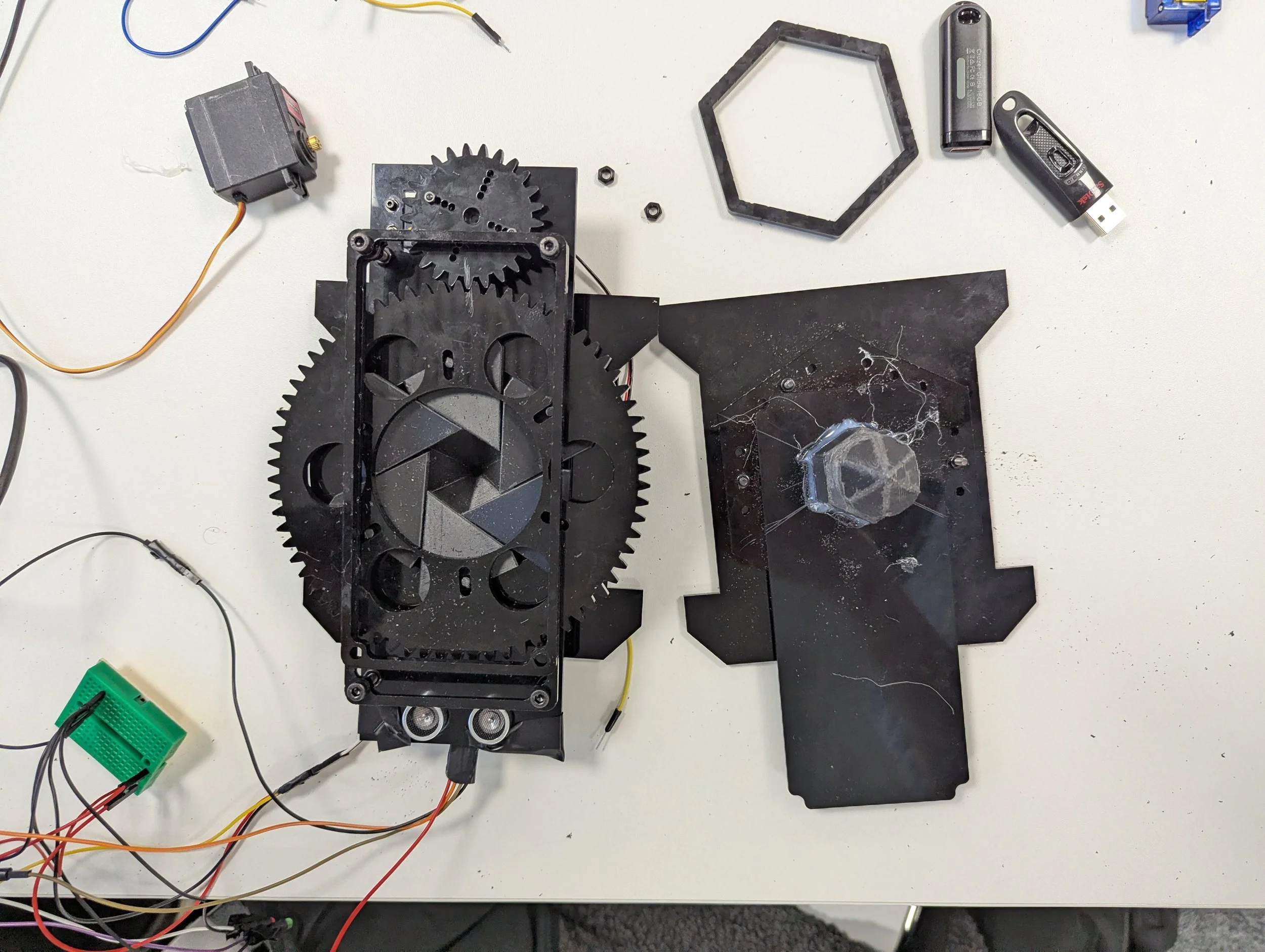

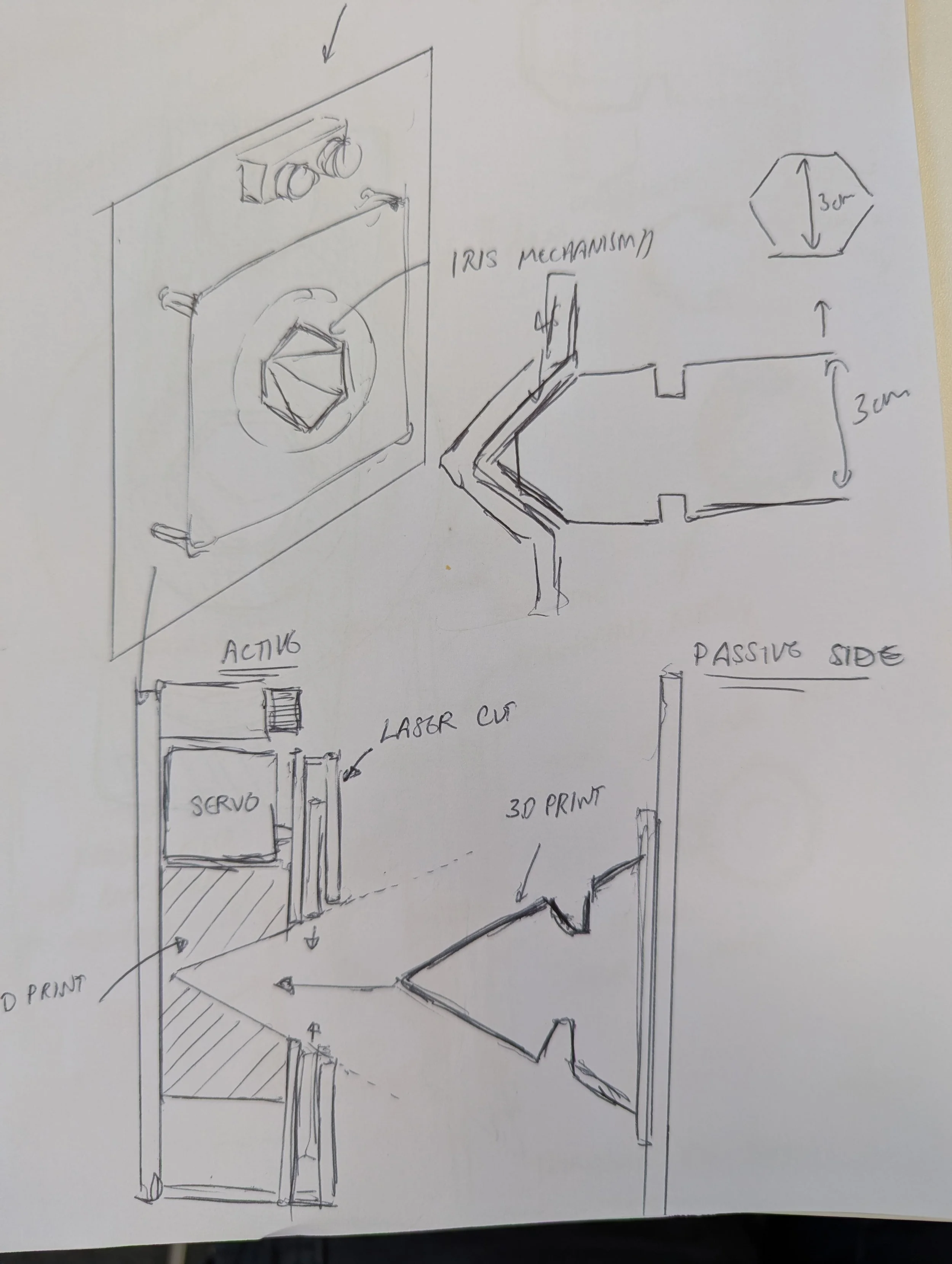

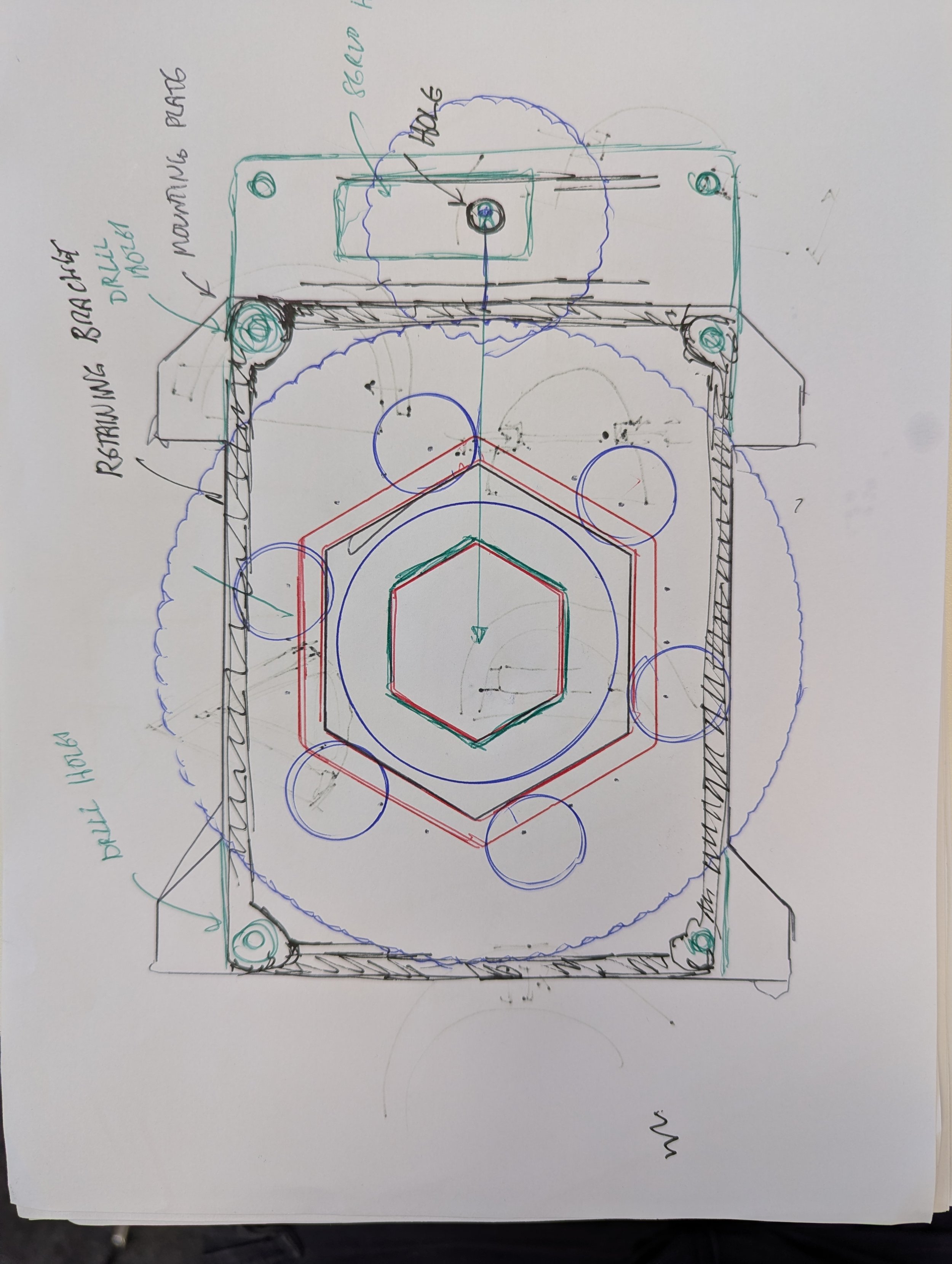

We discussed several approaches for the mechanism, firstly investigating existing mechanisms such as the NASA Docking System. Three shortlisted designs were considered: a lock and key, grabber arm, and Iris Mechanism. Each design was sketched up on paper and we carefully considered each designs advantages and disadvantages. Ultimately the Iris Mechanism was selected due to the variable scale of the locking mechanism and also the self centring behaviour due to the shape of the passive piece. Another consideration was that the Iris mechanism due to its hexagonal clamping profile would stop rotations of the passive satellite whilst in orbit and also provide even force around the passive docking adapter reducing wear.

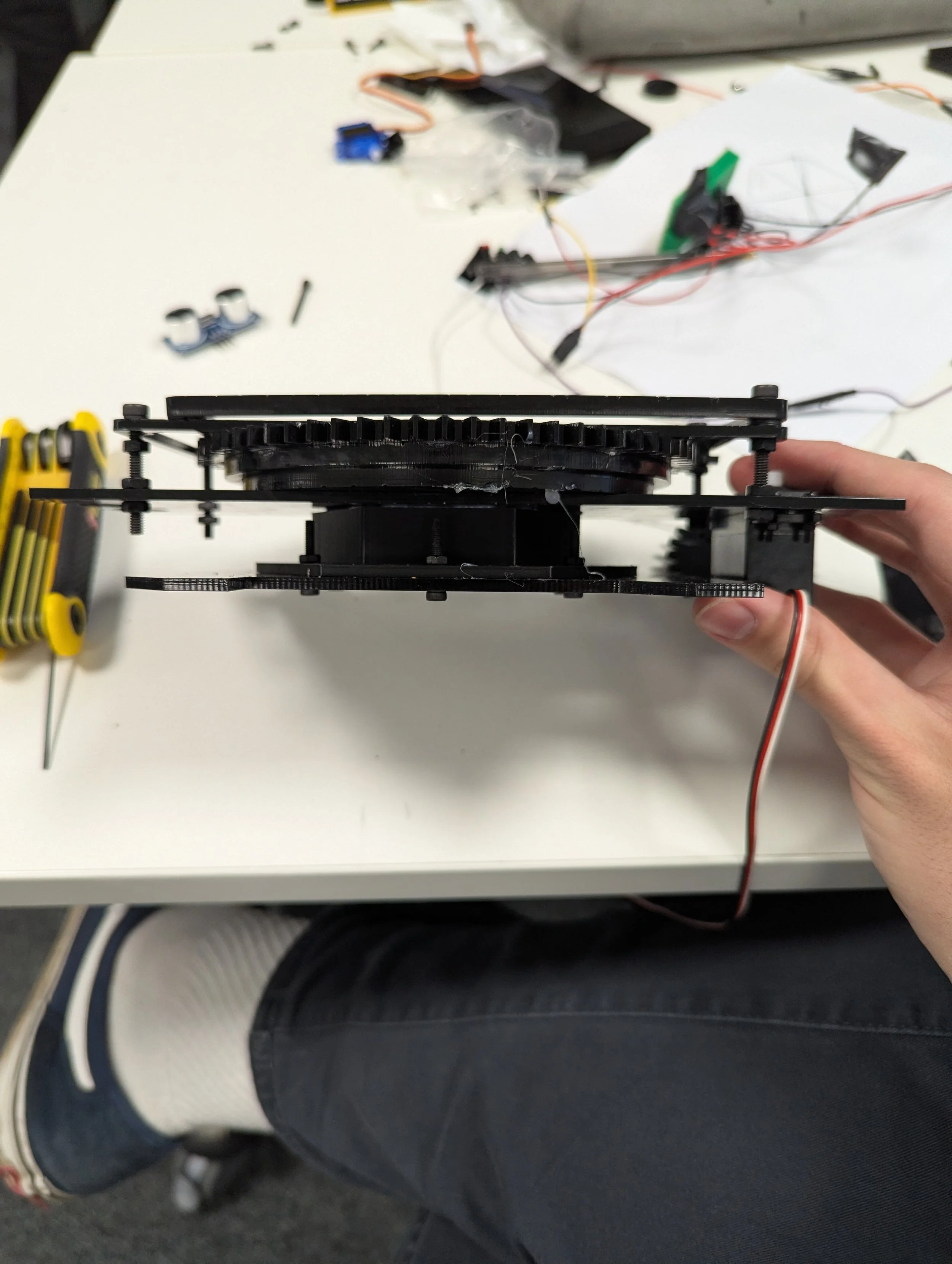

The design was made in CAD via 3dx and Fusion 360. The decision to go laser cut acrylic for the mechanism was due to the smooth surface of acrylic, reducing friction in the mechanism. It also allowed for faster prototyping where pieces were available in minutes rather than hours. The only pieces 3d printed where the iris shutter pieces and the passive docking piece. An ultrasonic depth sensor was also included to give readouts on the distance of the passive satellite from the active one allowing for more precision in docking. The design was successful, allowing for docking from imperfect angles thanks to the self centring behaviour and a strong docking link thanks to the irish mechanism.

Project Length: 1.5 days